Step-by-Step Guide: Performing Vibration Testing Using a Vibration Table

In the packaging and manufacturing industry, ensuring the durability of products during transportation is essential. One of the most effective methods to simulate transportation conditions is vibration testing. This test is performed using a vibration table, a precision-engineered testing instrument designed to replicate the vibrations experienced during handling, shipping, and transit. In this blog, we’ll walk you through a step-by-step guide to performing vibration testing using a vibration table, along with key insights about vibration table design, cost, and leading manufacturers and suppliers.

What is a Vibration Table?

A vibration table is a specialized testing instrument used to simulate the real-world vibration conditions that packages, containers, and other materials experience during transportation. It is widely used in industries such as packaging, automotive, electronics, and consumer goods to evaluate product integrity and package performance.

By using a vibration table, manufacturers can assess whether their packaging design is capable of protecting the product against shocks and vibrations that occur in trucks, trains, or during handling.

Importance of Vibration Testing

Before delving into the testing procedure, it’s important to understand why vibration testing is necessary:

-

Ensures product safety: It helps determine if the product or packaging can withstand road or air transport vibrations.

-

Prevents product damage: Identifies weak points in packaging or design before shipment.

-

Meets quality standards: Many international packaging standards like ASTM D999 or ISTA 1A mandate vibration testing for transit reliability.

-

Improves design efficiency: Helps optimize packaging and reduce material costs without compromising protection.

Vibration Table Design and Working Principle

A vibration table design typically includes:

-

Vibrating platform: The surface on which the test specimen is placed.

-

Electric motor: Provides oscillating motion to the platform.

-

Control panel: Allows users to adjust vibration frequency and amplitude.

-

Shock absorbers: Prevent excessive vibration transfer to the base or surrounding area.

The machine works on a simple principle — it generates controlled vibrations (vertical or rotary) that mimic the actual transportation conditions. The test specimen (usually a packaged product) is placed on the platform, and vibrations are applied for a specific duration to study their impact.

Step-by-Step Guide: Performing Vibration Testing Using a Vibration Table

Step 1: Prepare the Test Sample

Choose the product or packaging that needs to be tested. Make sure it’s packed as it would be for actual shipment — including inner cushioning, labels, and closures.

Step 2: Place the Sample on the Table

Position the package on the vibration platform. The orientation (vertical, horizontal, or inclined) depends on your testing standard or product type.

Step 3: Set the Parameters

Using the control panel, set the desired frequency, amplitude, and duration of vibration.

-

Common test frequencies range between 3 to 100 Hz, depending on simulation needs.

-

Duration can vary from a few minutes to several hours.

Step 4: Start the Vibration Test

Turn on the vibration table and allow it to operate as per the set parameters. Observe the package behavior during testing to check for visible damage or displacement.

Step 5: Stop and Inspect

After the test duration ends, stop the machine and carefully inspect the product and packaging for signs of damage such as cracks, seal failures, or leakage.

Step 6: Record Results

Document all findings, including the vibration parameters, test duration, and observed damage (if any). This data helps manufacturers improve packaging design and ensure better protection.

Choosing the Right Vibration Table

When selecting a vibration table, consider the following factors:

-

Load capacity: Must accommodate the weight of your product or package.

-

Frequency range: Choose a model that allows adjustable vibration frequencies for different test types.

-

Platform size: Ensure it suits your product dimensions.

-

Control features: Digital displays and adjustable controls enhance testing accuracy.

-

Build quality: A durable design ensures consistent performance over time.

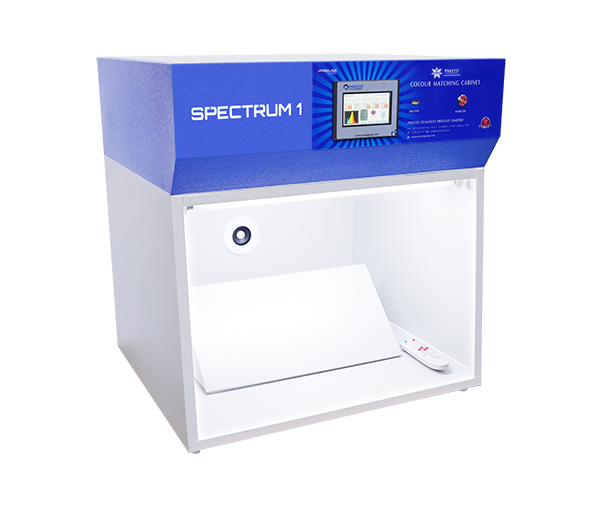

If you’re looking for a reliable testing solution, Presto Stantest Pvt. Ltd. offers high-quality vibration tables designed as per international standards. These tables provide accurate simulation of transport vibrations, ensuring that your products remain safe and intact until they reach the customer.

Vibration Table Cost and Price Considerations

The vibration table cost depends on factors such as:

-

Table size and load capacity

-

Vibration type (rotary or vertical)

-

Frequency control system (manual or digital)

-

Additional features like data recording or automation

In India, vibration table price can range from depending on the specifications and brand. Presto offers competitively priced solutions without compromising on quality or accuracy.

Top Vibration Table Manufacturers and Suppliers in India

When purchasing a vibration table, it’s crucial to choose a reputed manufacturer or supplier to ensure quality and reliability. Some key points to look for in a vibration table manufacturer include:

-

ISO-certified production facilities

-

Compliance with ASTM or ISTA standards

-

Availability of after-sales support and calibration services

Presto Group, one of the leading vibration table manufacturers and suppliers in India, is known for its precision-engineered instruments. The company’s tables are built to deliver high performance, long-term durability, and consistent results.

Applications of Vibration Table

-

Packaging Industry: To test boxes, cartons, and containers.

-

Automotive Industry: For testing components like dashboards, sensors, or panels.

-

Electronics: To evaluate product stability under vibration conditions.

-

Pharmaceuticals: For checking the integrity of bottles and blister packs.

Conclusion

A vibration table is an essential instrument for ensuring product safety during transportation. It helps manufacturers identify potential weak points in packaging and design, reducing the risk of product damage and financial losses. Whether you’re a packaging professional or a quality control engineer, performing vibration testing using a reliable vibration table can significantly improve your product’s transit performance.

If you are looking for a high-quality vibration table at an affordable price, contact Presto Group — one of the top vibration table manufacturers and suppliers in India.

📞 Call us at: +91-9210 903 903

📧 Email: info@prestogroup.com

🌐 Visit: https://www.testing-instruments.com/contact/

Comments

Post a Comment