Exploring Essential Testing Instruments: Functions and Pricing Guide

In various industries, ensuring the quality and performance of materials and products is paramount. To achieve this, companies rely on a range of sophisticated testing instruments. Let's delve into five essential testing instruments, their functionalities, and pricing considerations:

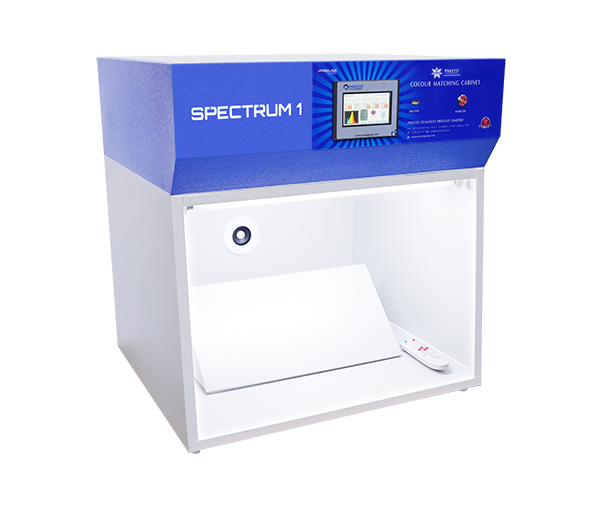

1. Color Matching Cabinet: A color matching cabinet is indispensable for industries where accurate color assessment is crucial, such as textiles, printing, and automotive. It provides standardized lighting conditions to evaluate color consistency and accuracy across materials. Prices vary based on size, features, and brand reputation, ranging from a few hundred to several thousand dollars.

2. Torque Tester: Torque testers are essential for assessing the torque force applied to fasteners, closures, and components in manufacturing and assembly processes. They ensure proper tightening and prevent under or over-torquing, which can compromise product integrity. Prices depend on torque range, accuracy, and additional features, typically ranging from hundreds to thousands of dollars.

3. Muffle Furnace: Muffle furnaces are used for high-temperature applications such as heat treatment, annealing, and material testing in laboratories and research facilities. They provide controlled heating environments with uniform temperature distribution. Prices vary based on chamber size, maximum temperature, heating elements, and programmable features, ranging from a few hundred to several thousand dollars.

4. Coefficient of Friction Tester:

Coefficient of friction testers measure the frictional resistance between two surfaces in contact, essential for assessing the slipperiness and wear characteristics of materials in packaging, automotive, and manufacturing industries. Prices depend on the testing method (horizontal or inclined plane), software capabilities, and sensor technology, typically ranging from hundreds to several thousand dollars.

5. Cobb Tester: A Cobb tester evaluates the absorbency and surface water resistance of paper and paperboard, critical for quality control in the paper industry. It measures the time taken for a specific volume of water to be absorbed by the material. Prices vary based on size, automation features, and precision, ranging from a few hundred to several thousand dollars.

In conclusion, investing in quality testing instruments is essential for maintaining product quality, ensuring compliance with industry standards, and enhancing customer satisfaction. While prices vary depending on factors such as features, specifications, and brand reputation, the value they provide in terms of quality assurance and efficiency far outweighs the initial investment. By choosing the right testing instruments for specific applications, businesses can streamline processes, minimize defects, and achieve greater success in their respective industries.

This blog provides a comprehensive overview of essential testing instruments and their significance across various industries. The detailed breakdown of functionalities and pricing considerations offers valuable insights for businesses seeking to invest in quality assurance equipment. By emphasizing the importance of these instruments in maintaining product quality and meeting industry standards, the blog effectively highlights their role in enhancing efficiency and customer satisfaction. Overall, it's a well-researched and informative guide for companies looking to make informed decisions about their testing equipment needs.

ReplyDelete